Benefits of FRP Composites

Environmental Advantages of FRP Composites

Composite products made of Fibre Reinforced Polymer or FRP are poised as the modern day material owing to its superiority in terms of its adjustable characteristics (based on resin selection) such as high strength-to-weight ratio, commendable thermo-mechanical, and corrosion resistant properties. One can easily comprehend the usefulness of this material from these physical properties. Treadwell and many markets recognise the immense potential in making durable structural systems.

Advantages of FRP1:

- FRP is light in weight and helps in cutting expenses on labour and installation. FRP increases construction speed that further reduces environmental impacts.

- Fibreglass composite materials are not just durable; they also have high strength as compared to traditional materials. Users can expect less material usage to attain better or similar performance compared to conventional materials which result in lessened resource use as well as waste production.

- FRP has great potential in further maximising the longevity of existing as well as new and structures that can resist the harsh effects of weathering, degradation, and aging in severe environments.

- FRP composite materials are extremely resistant to corrosion and rot. Besides these, they present a longer and yet more efficient service life. FRP based products hardly require an energy-intensive replacement nor much maintenance.

Recycling Advantage of FRP Products

At juncture, FRP can be recycled. It must be said that it is not currently economically viable on a large scale. However, there is great potential in which products can be developed from the recycling process to make the process viable in the future.

Varied recycling techniques can be implemented to develop different components, further paving the route for varied recycling avenues. These products can be formed by making use of recyclate material that is generated by crushing the composites and prepregnated wastes from off cuts when producing components to particular dimensions. The individual components which include fillers or fibres from chemical or thermal removal can be converted into components2 .

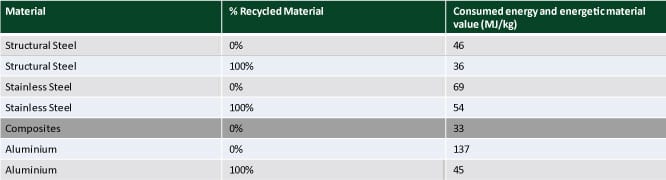

Regardless, based on research conducted, it can be deduced that the production of FRP components consumes less energy and produces less greenhouse effect verses recycling steel and aluminium. To substantiate the case, a study in Rotterdam in 20033 compared energetic values of various material options in the construction of a pedestrian bridge and yielded the results below. Clearly composites present lower energy consumption.

1 Lee, L.S. & Jain, 2009, The role of FRP composites in a sustainable world

2 School of Metallurgy and Materials, University of Birmingham. 2010. The Reuse and Recycling of Glass Fibre Waste. Available at: http://etheses.bham.ac.uk/1342/1/Wait11MRes_A1b.pdf, viewed November 2016

3 Daniel, Ryszard A., Environmental Considerations to Structural Material Selection for a Bridge. European Bridge Engineering Conference, Rotterdam, March 2003.