Treadwell Fibreglass Reinforced Plastics (FRP)

Fiberglass Reinforced Plastics (FRP) is an excellent choice of construction material in harsh and corrosive environments. Traditional building materials have had their place in time, but for the modern and smart, Treadwell’s FRP products is the intelligent choice – wood rots, aluminium dents and steel rusts.

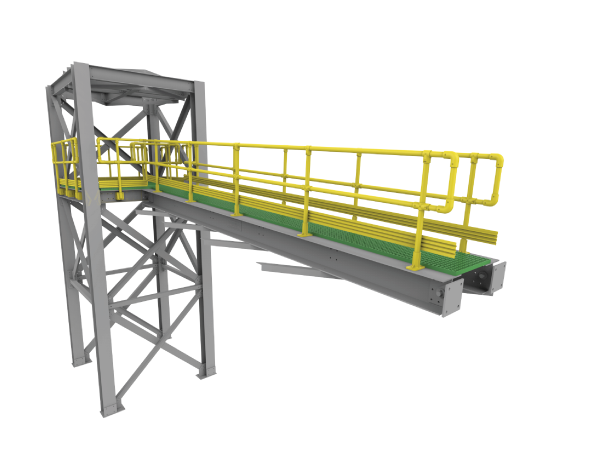

Treadwell’s FRP range of grating, handrails, ladders, structural profiles, covers and more possesses strength similar to steel at a fraction the weight. This allows easy handling and requires little maintenance. It will not corrode (based on resin system selection), conduct electricity and is transparent to radio frequencies.

What is FRP

FRP is basically made of thermosetting resins and fibreglass. This adjustable combination of resin and glass fibres constitute the makeup of all fibreglass products. The resin brings the environmental and chemical resistance to the product and is the binder for the glass fibre in the structural laminate. Based on the chemical and environmental circumstances (given by the customer or user), a resin type is selected. In general, Treadwell works with four types of resin (I,O,V and P Series). Read more about our resin systems Here.

Furthermore, we have different options of resin surface with grit to be selected. This is again based on the application and processes the final product will be utilised for. You can find out more Here. With regard to composing these ingredients and choosing the right resins for the right applications, advice on practical usage and/or actual design of FRP structures, selecting the right manufacturer is highly important.

GRP or FRP?

In general, Treadwell utilises FRP as the most common term for this composite material. However, there is another common use of the term GRP (Glassfibre Reinforced Plastics). This term is widely used in Europe. The both refer to the same material but ‘fibreglass’ is more commonly applied when talking about FRP.

Benefits of FRP

Treadwell takes pride in educating others with the many benefits that FRP possesses over conventional materials. Though traditional materials are still crucial today, with the advancement in FRP composites and the increasing benefits of FRP, the cause to use FRP has extended in various ways. In summary, FRP is the way of the future to allow a different and more flexible solution for design challenges in a multitude of environments.

Corrosion, Rust & Rot Proof

Treadwell’s superior resin systems offer exceptional resistance to acids, salts, and alkalis. At the same time, our FRP systems are rot and termite proof.

Areas of Application

Treadwell’s FRP products are constantly being found in more and more markets as FRP grows in acceptance. Typically, you can see our work and products in water and wastewater, recreational public infrastructure, utilities and rail, mining and mineral processing, and oil, gas and petrochemical industries. To find more detailed areas of application of our FRP products, please visit us Here.